Loose Powder Case Manufacturer

Made from high-quality materials, these cases ensure durability, functionality, and a sleek design that elevates product appeal. Ideal for loose powder, setting powder, or mineral powder, our custom cases provide the perfect blend of style and practicality to create a lasting impression in the beauty market.

Loose Powder Case Manufacturer

Made from high-quality materials, these cases ensure durability, functionality, and a sleek design that elevates product appeal. Ideal for loose powder, setting powder, or mineral powder, our custom cases provide the perfect blend of style and practicality to create a lasting impression in the beauty market.

Explore Our Loose Powder Case Collection

Discover a wide range of custom loose powder cases crafted with precision and style. From modern, minimalist designs to eco-friendly options, our collection provides versatile solutions to match every brand's unique aesthetic. Choose from a variety of shapes, materials, finishes, and sizes, all tailored to elevate your packaging and create a lasting impression in the beauty industry.

Loose Powder Case 4012

Loose Powder Case 4010

Loose Powder Case 4009

Loose Powder Case 4007

Loose Powder Case 4006

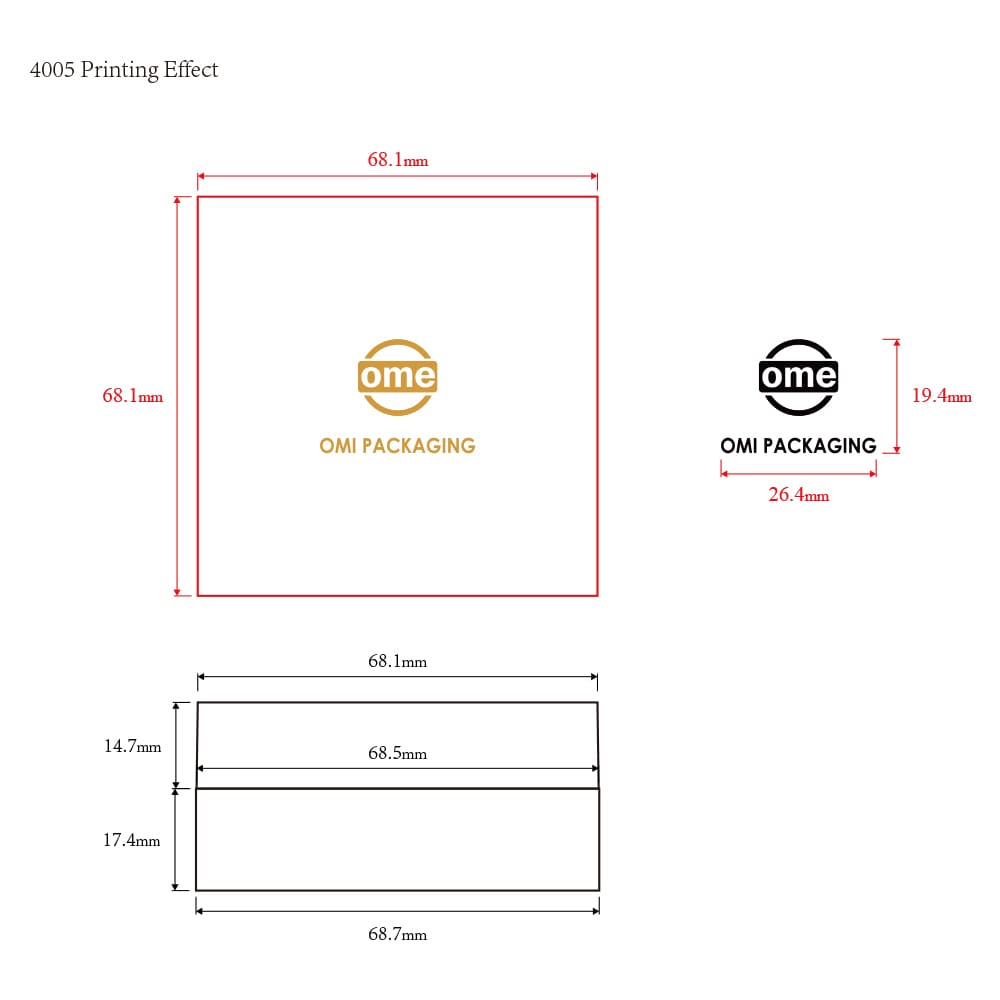

Loose Powder Case 4005

Explore our catalog for additional designs and find the perfect loose powder case to elevate your brand.

Request a quote for more details

Everything You Need to Know About Loose Power Case

Choosing the right loose powder case for your brand involves selecting the ideal material and design. Materials like MS, ABS, AS, and PP offer excellent durability, style, and versatility. While ABS provides robust, sleek designs, AS adds a polished, high-end finish, and PP ensures a lightweight, cost-effective solution.

Design features such as sifters, magnetic closures, frosted or transparent finishes, and built-in mirrors enhance both functionality and the aesthetic appeal of your product. Customization options, including unique shapes, colors, surface finishes, and logo printing, allow you to create packaging that perfectly represents your brand’s identity.

Our advanced production capabilities guarantee flexible lead times, competitive MOQs, and efficient processes, all while meeting ISO 9001 quality standards. With sustainable packaging options and tailored designs, our loose powder cases are designed to meet your brand’s needs and stand out in the competitive cosmetics market.

Material Options for Loose Powder Case

Loose powder cases are available in various materials, each offering distinct advantages to match your brand’s needs. PETG is transparent and eco-friendly, making it an excellent choice for showcasing the product while supporting sustainability goals. ABS is durable and sleek, ideal for creating sturdy, stylish designs that stand the test of time. AS provides a polished, high-end finish that adds luxury to premium loose powder packaging.

By understanding the characteristics of each material, you can select the perfect combination of functionality, aesthetics, and eco-conscious design for your loose powder case packaging.

PETG is a popular choice for loose powder cases due to its excellent transparency and recyclability. It allows consumers to see the product inside, which is particularly beneficial for showcasing vibrant powders or colors. Its eco-friendly properties make it a great choice for brands that prioritize sustainability while maintaining a durable and functional design.

ABS is known for its sturdiness and sleek design, making it a reliable material for loose powder cases. It provides a smooth finish and is highly resistant to impact, ensuring that the case maintains its form and function even after repeated use. ABS is perfect for brands seeking a stylish yet durable packaging solution.

AS offers a premium, polished finish that elevates the aesthetic of loose powder cases, giving them a high-end look. This material is perfect for luxury brands, as its smooth surface enhances the visual appeal of the product. AS is also lightweight and highly durable, offering both elegance and practicality in cosmetic packaging.

Customization Choices for Your Brand

Quality Control in Loose Powder Case Production

At Ominatural, ensuring the highest quality standards for our loose powder case is a top priority. We follow a meticulous quality control process to guarantee that every product meets international benchmarks and exceeds customer expectations.

1. Strict Quality Control Process

Raw Material Inspection: We source premium materials such as PETG, ABS, and AS, thoroughly inspecting them for consistency, durability, and visual appeal before production begins.

In-Process Monitoring: Each phase of production, from molding to surface finishing, is carefully monitored to ensure precision, uniformity, and high-quality results.

Post-Production Testing: Every batch undergoes comprehensive testing to confirm functionality and durability, including:

- Closure Security: Ensuring secure and smooth closure mechanisms, whether snap or magnetic.

- Durability Checks: Testing resistance to everyday wear, scratches, and impact.

- Functionality Testing: Verifying the seamless operation of all functional components, such as sifters and closures.

2. Sample and Mass Production Consistency

We understand the importance of delivering products that align with initial samples. To ensure this:

- Prototype Matching: Every production batch is matched with approved prototypes for precision.

- Color and Finish Checks: Advanced equipment ensures color accuracy and finish consistency.

- Final Inspection: Our team conducts a thorough inspection before packaging and dispatch.

3. Certifications and Compliance

Our commitment to quality is backed by industry-leading certifications, ensuring reliability and compliance:

- ISO 9001:2015: Reflecting our strong focus on consistent quality management.

- CE Certification: Guaranteeing safety and compliance with European market standards.

- SA8000: Demonstrating our dedication to ethical manufacturing practices.